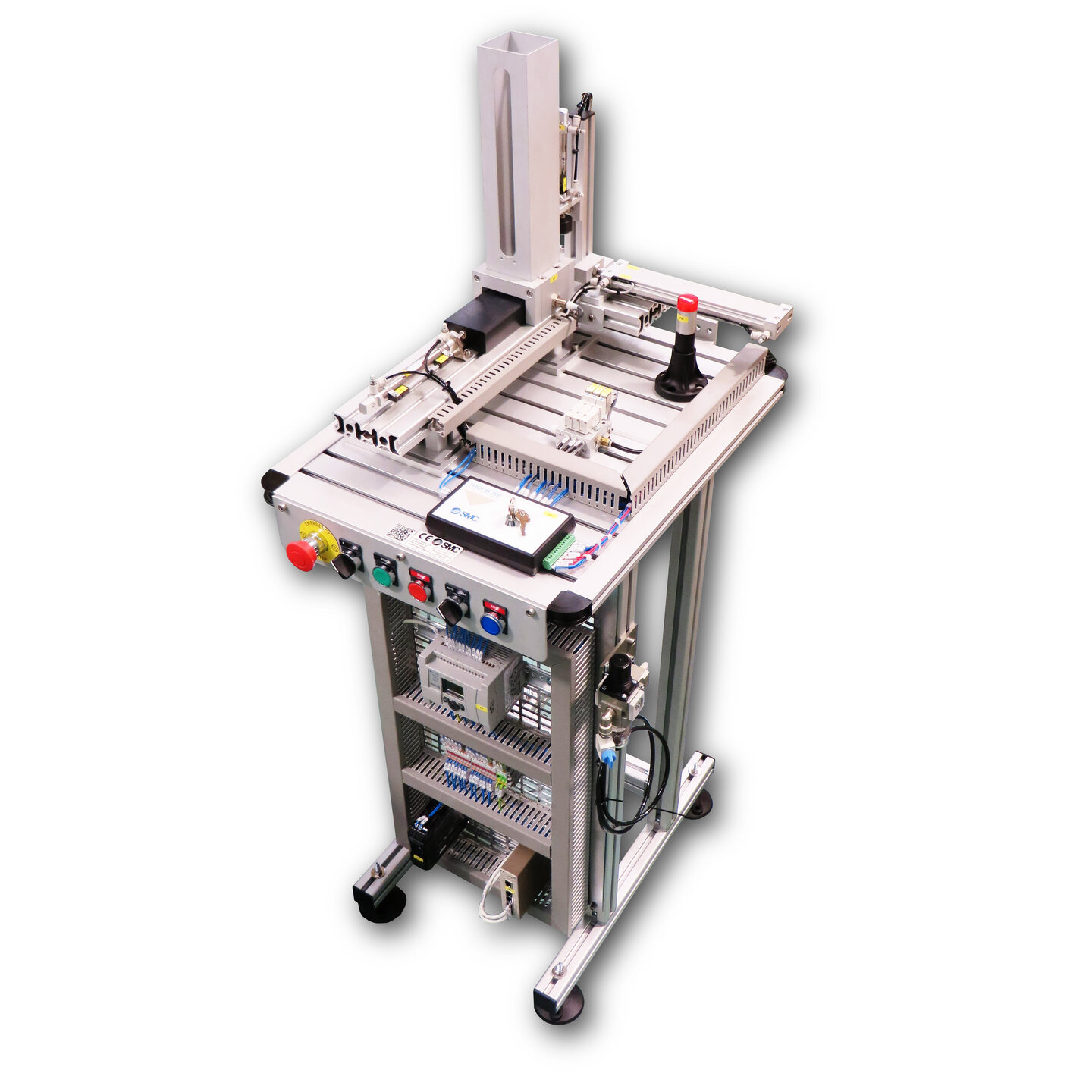

FAS-200 stations

Each of the FAS-200 system stations carries out part of the process. FAS-200 comprises up to 18 independent stations with integrated control. This modular equipment features a higher number of stations in the same space, which means that more users will be able to work at the same time.