Commitment to Sustainability

By using reusable materials in the manufacture of products, this system eliminates the need for disposable consumables. In addition, its energy efficiency, measured in real time, and optimised operating pressure, ensures lower energy consumption, thus contributing to a more sustainable future.

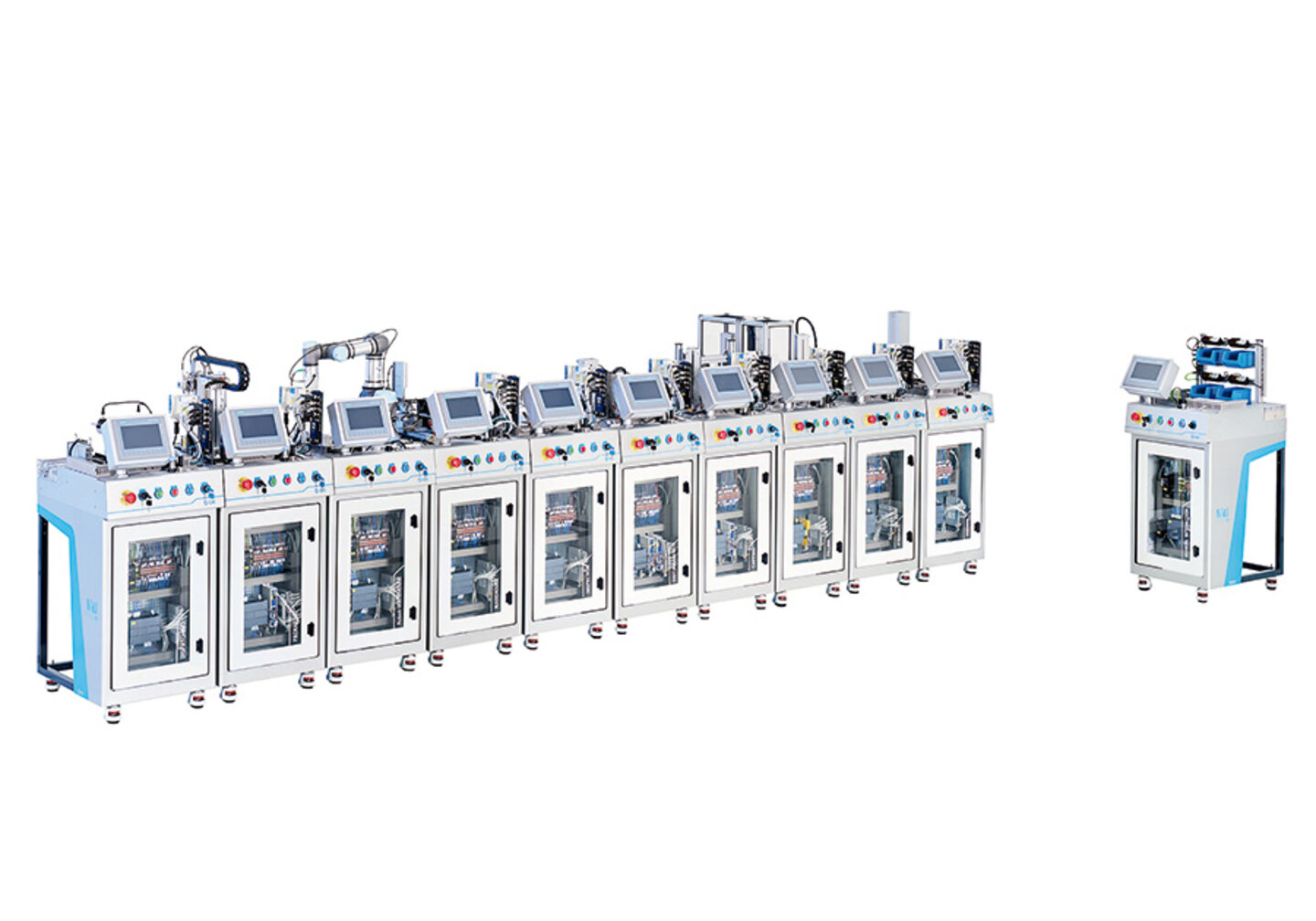

New innovative design

More attractive, ergonomic, compact and modular design. This modularity allows for scalable expansion over time, adapting to the changing needs of users and ensuring a lasting investment in technological training.

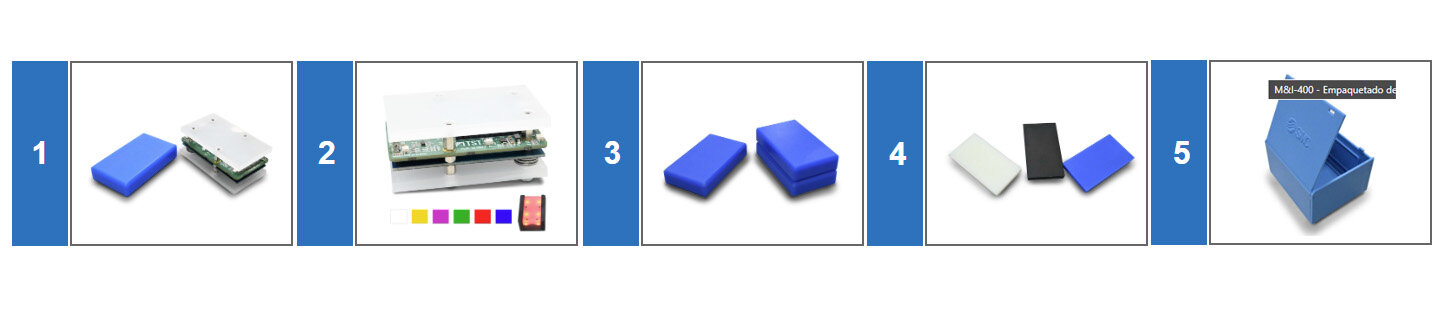

Innovative transport system concept

The M&I-400 conveyor system introduces an innovative approach by integrating its own PLC, making it a cyber-physical system. In addition, the elimination of belts and bearings significantly reduces maintenance requirements, while minimising noise and dust generation. The transparent methacrylate cover provides a clear view of the internal components, facilitating monitoring and diagnostics.

Integration of IoT technologies

With the inclusion of Wifi AP, data storage in a database and monitoring via M&I-MES, the M&I-400 takes connectivity and data collection to the next level.

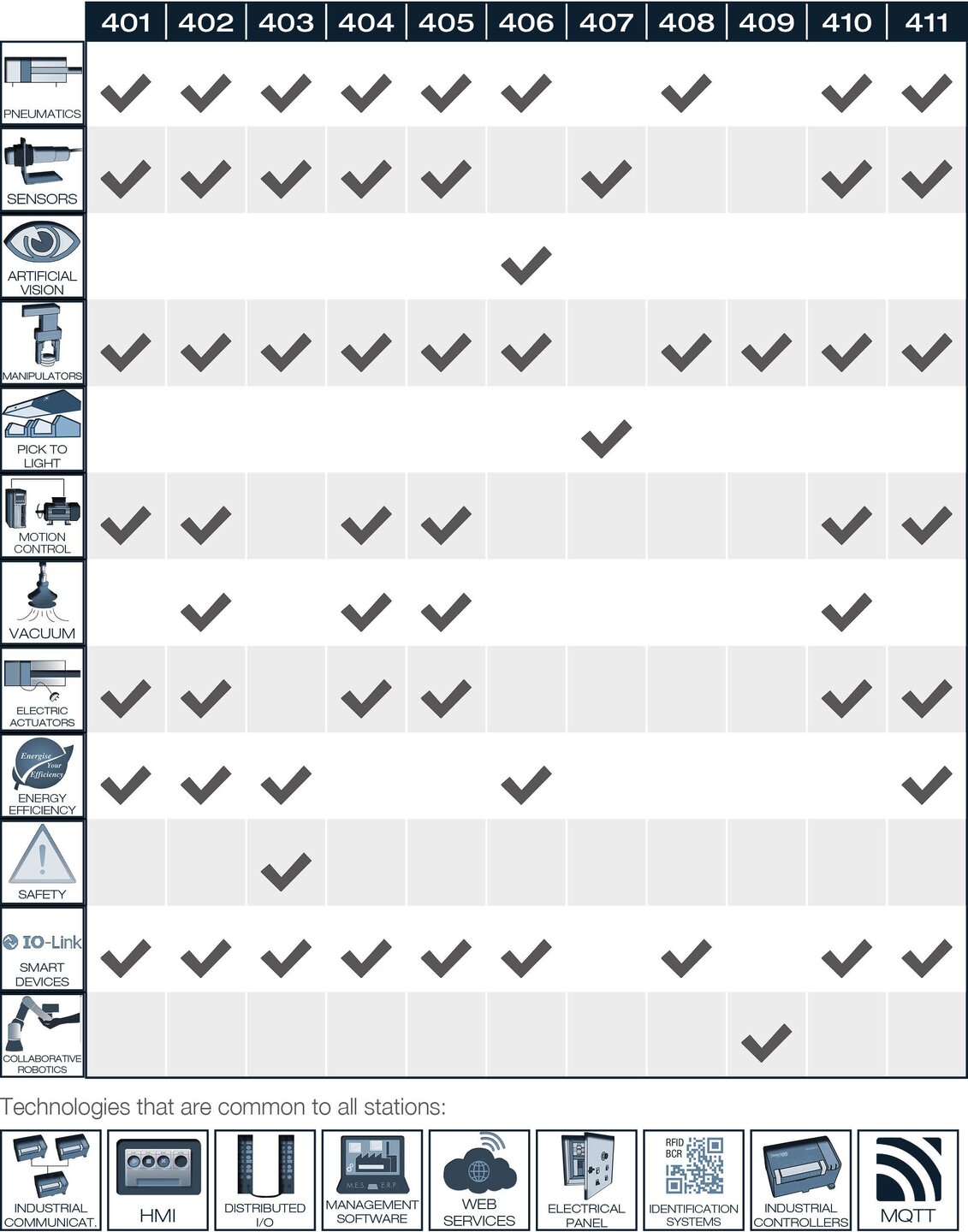

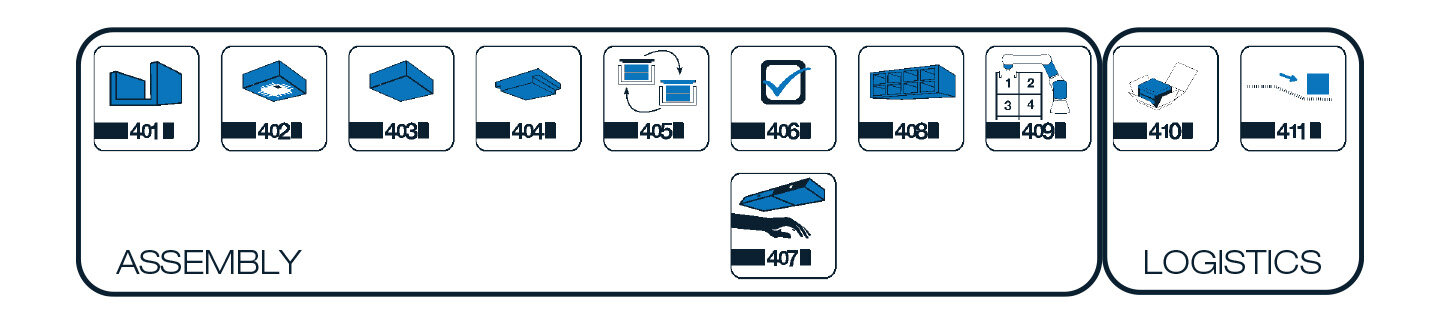

Wide variety of technologies in a smaller space

The M&I-400 system stands out for its ability to integrate a wide range of technologies in a smaller space. It also introduces innovations such as MQTT and Pick to Light, along with enhanced features such as Arduino-based iProduct and RFID-based KeyID.