FMS-200 - Flexible integrated assembling systems

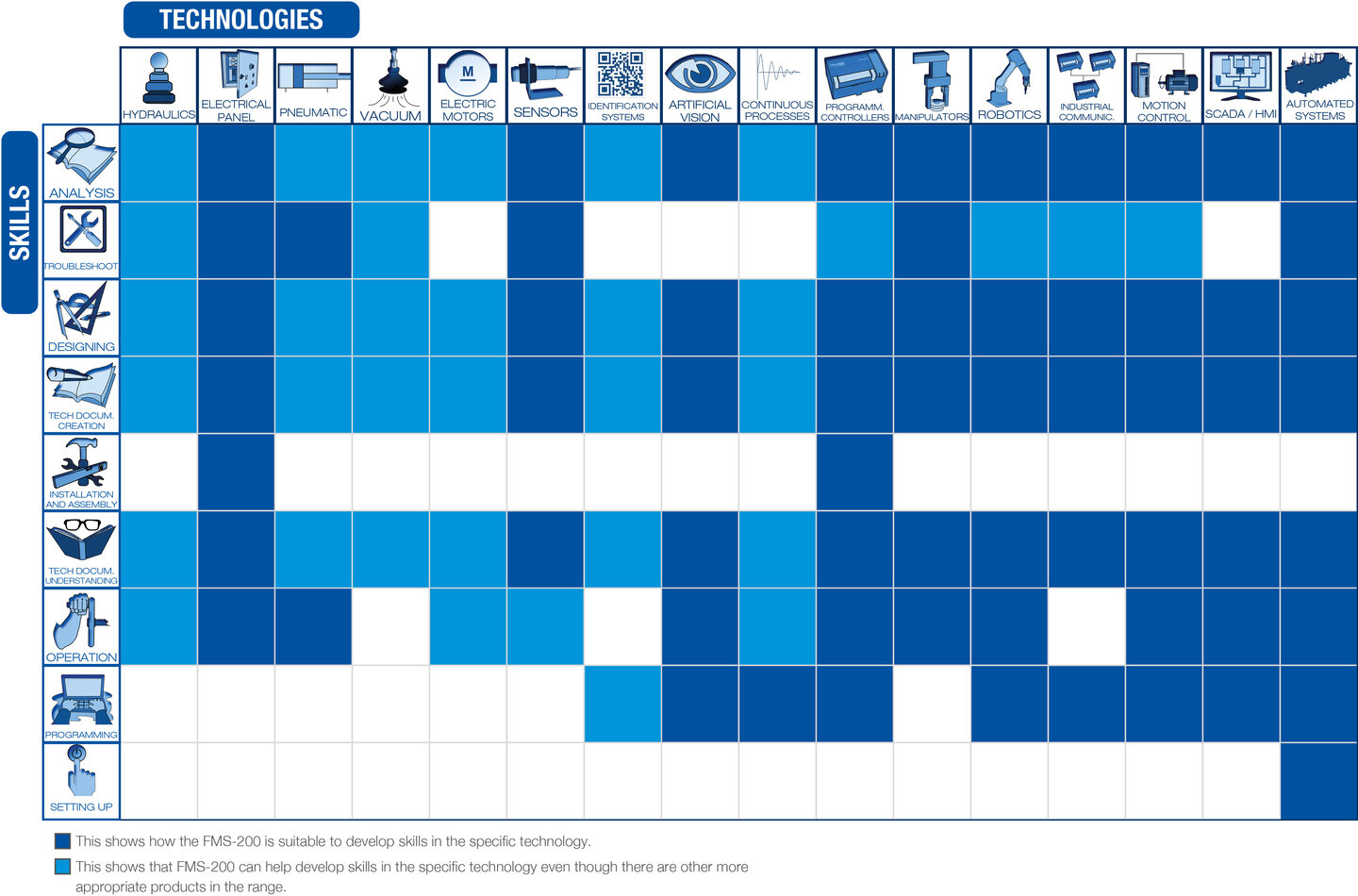

A fully modular and flexible didactic equipment, made of industrial components, that allows an integrated training in industrial automation / mechatronics.

A fully modular and flexible didactic equipment, made of industrial components, that allows an integrated training in industrial automation / mechatronics.

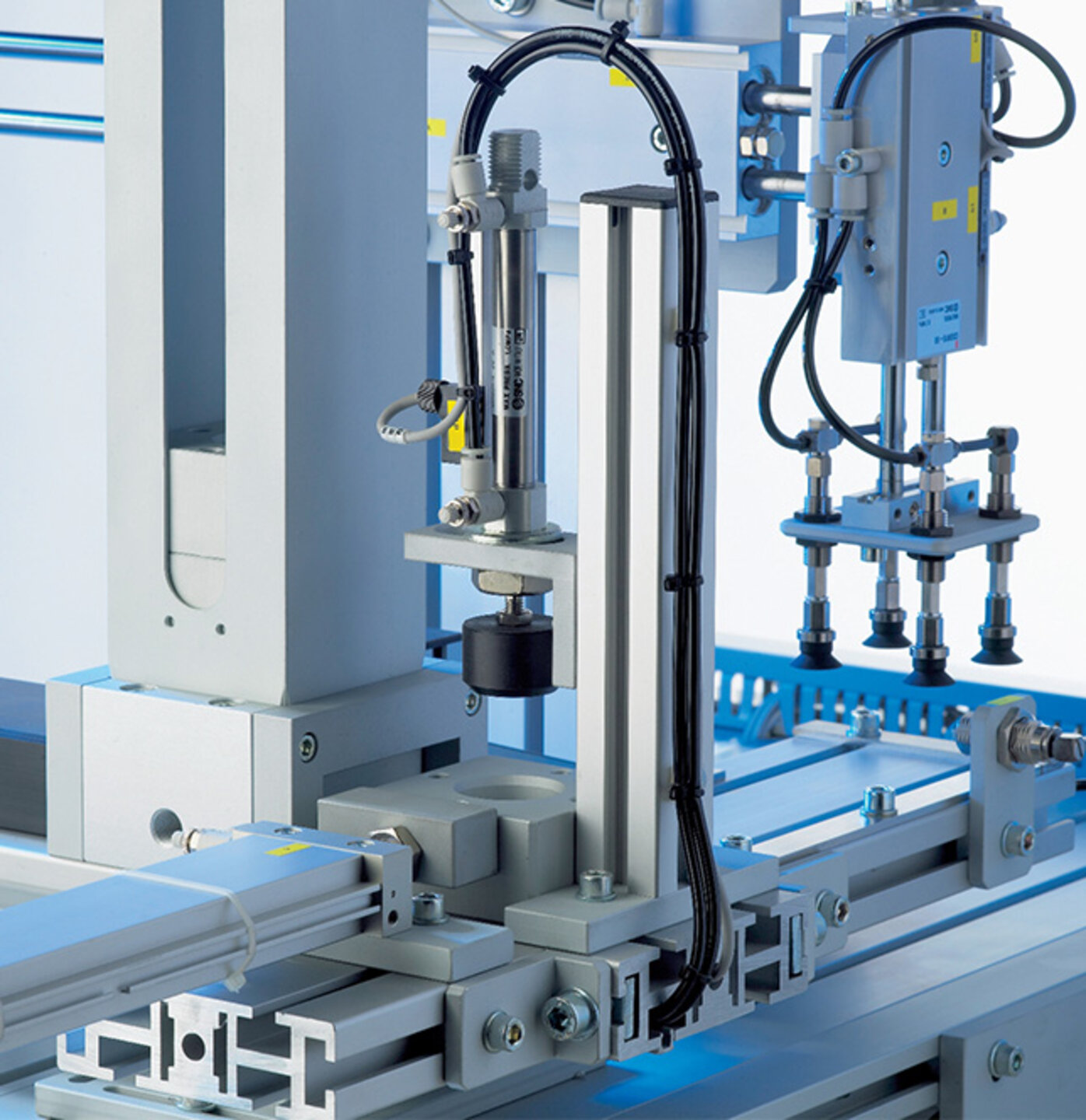

Integral training in industrial automation. The different process stations assemble a turning mechanism. To provide the system with greater flexibility, stations adapt to a wide variety of assemblies, introducing variations in the materials, colours and part sizes. The combination of all these possibilities means that a total of 24 different assemblies can be obtained enabling the use of production management strategies. The system includes a whole series of feeding, handling, verification and loading operations etc. carried out using components from different technologies (pneumatics, hydraulics, sensors, robotics, communications, control and HMI.).FMS-200 includes the breakdown simulation system which generates up to 16 different breakdowns to be diagnosed by the user.

Image gallery

2 versions

This is a rectangular transfer system through on which pallets containing the workpiece circulate around the stations.

In this FMS-200 version, each of the stations includes an individual transfer section. Multiple combinations of layouts can be developed, with the option of joining stations at 90º or 180º (section in curve, straight section).

With this system you could...

Increase your knowledge of industry 4.0 technologies and develop advanced skills in mechatronics utilizing a real industry-based platform.

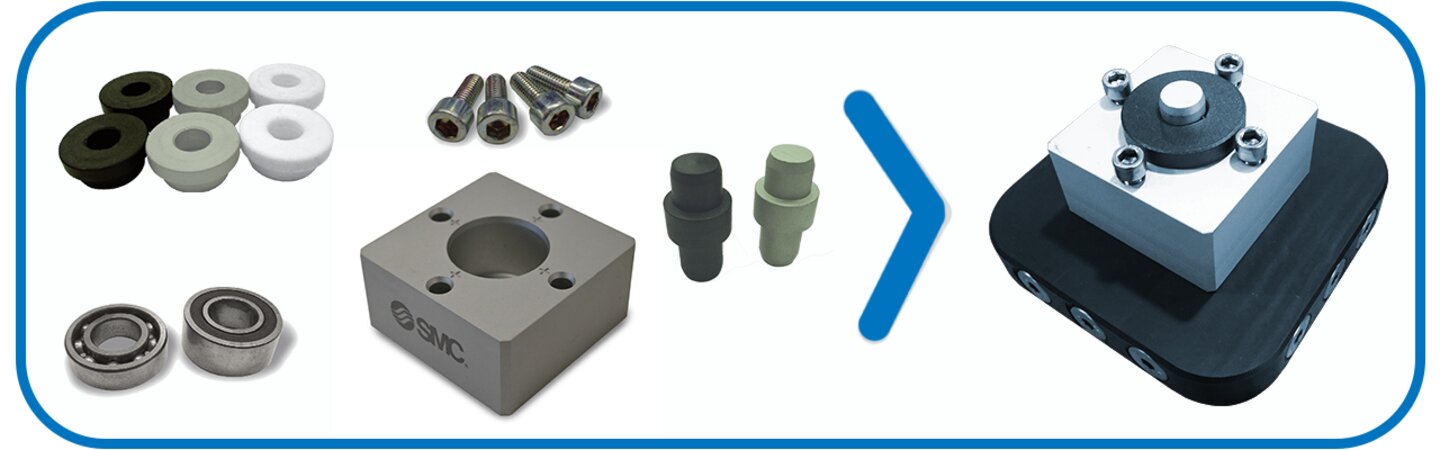

Turning mechanism