MAP-205 SE I4.0

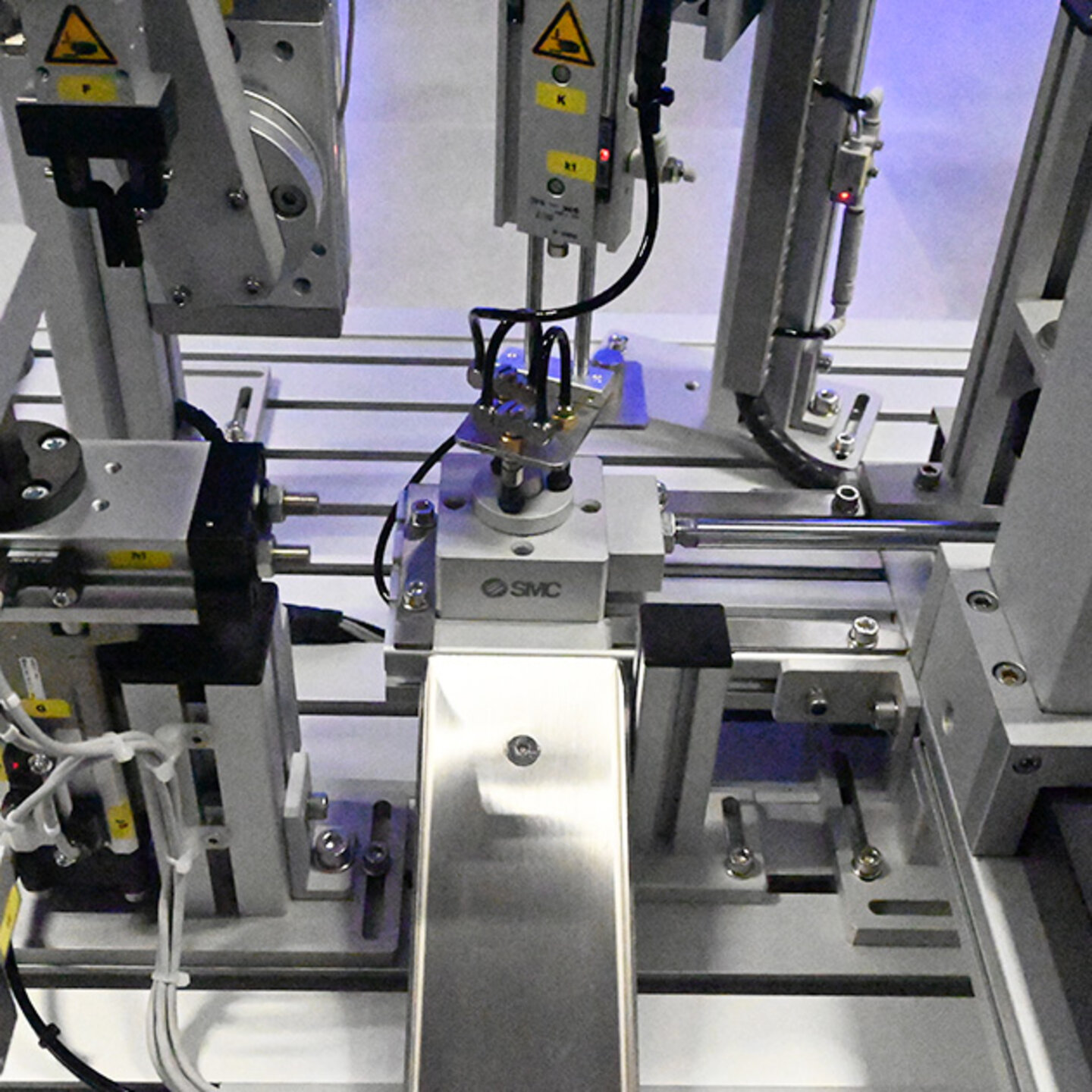

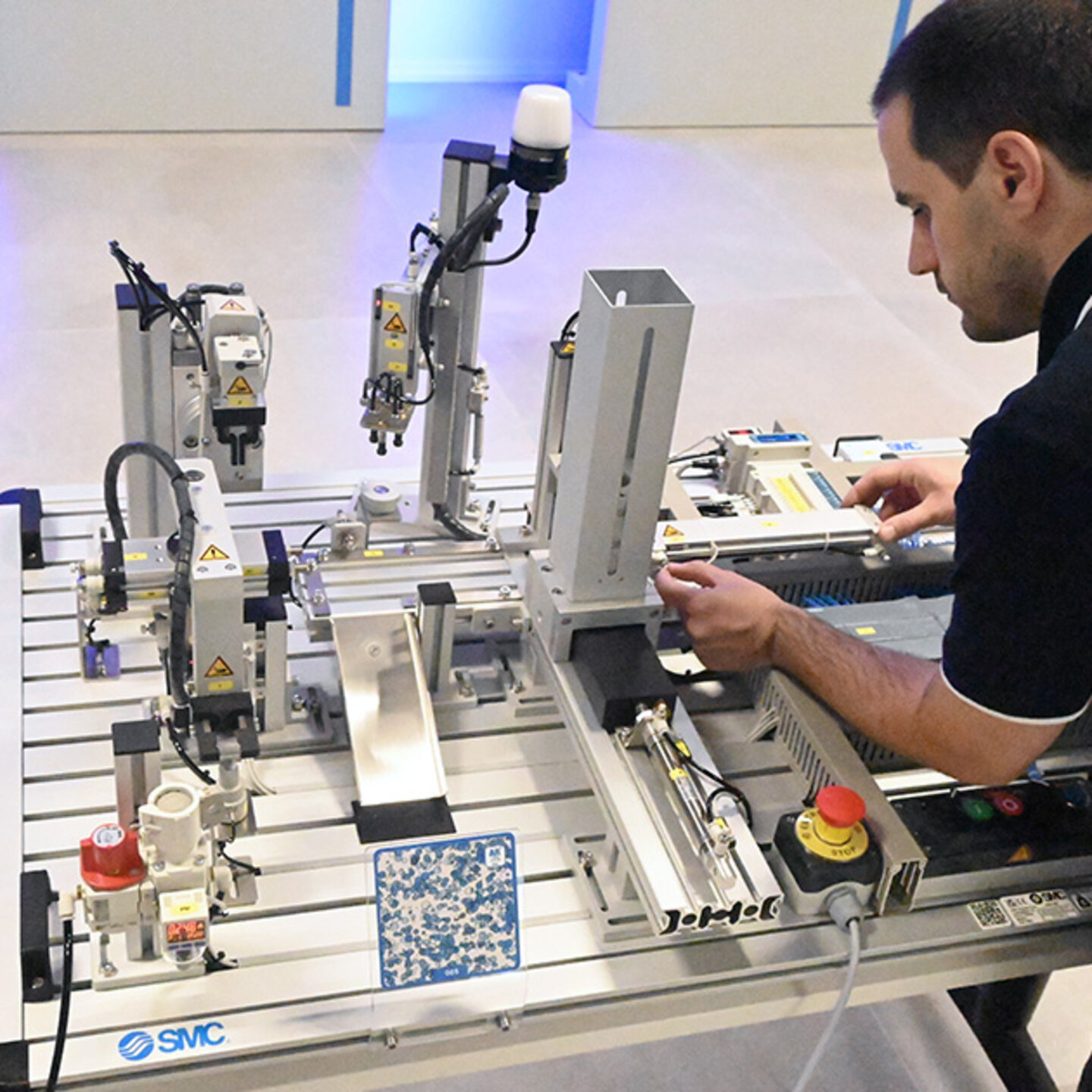

Automated Assembly System 4.0, where the assembly and disassembly of a rotary mechanism are performed, allowing mastery of mechatronics and Industry 4.0 technologies.

Automated Assembly System 4.0, where the assembly and disassembly of a rotary mechanism are performed, allowing mastery of mechatronics and Industry 4.0 technologies.

Assembly Minicell 4.0 evolves from traditional mechatronics into an intelligent solution ready to meet the challenges of Industry 4.0. Thanks to the integration of advanced technologies such as augmented reality, IoT connectivity, and energy efficiency, this system not only automates assembly processes but also optimizes them according to production needs.

Image gallery