FAS-200 - Flexible assembly system

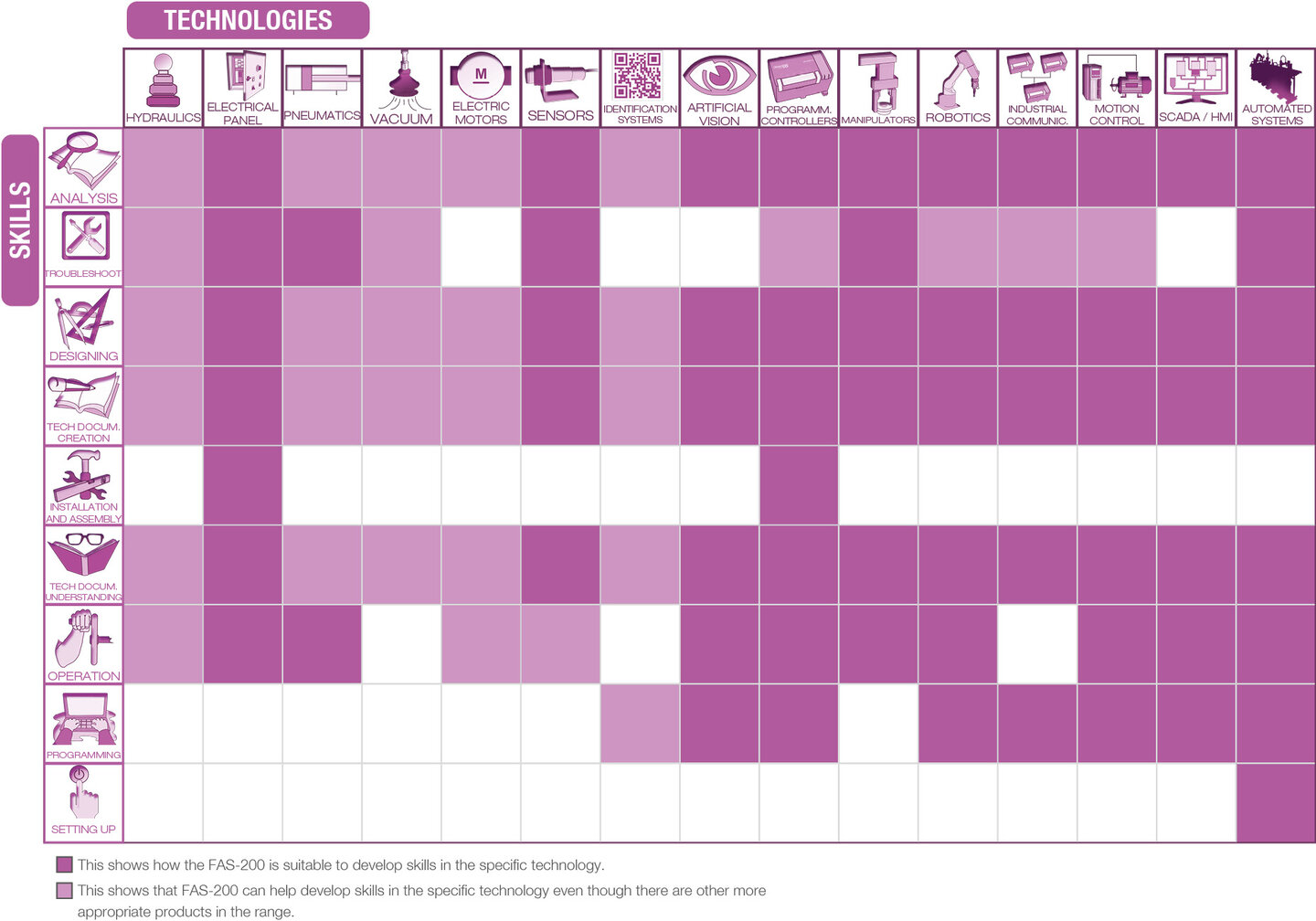

FAS-200 - Flexible and compact didactic equipment for mechatronics and automation skills training. Many technologies in the same system.

FAS-200 - Flexible and compact didactic equipment for mechatronics and automation skills training. Many technologies in the same system.

Image gallery

With this system you could...

Increase your knowledge of industry 4.0 technologies and develop advanced skills in mechatronics utilizing a real industry-based platform.

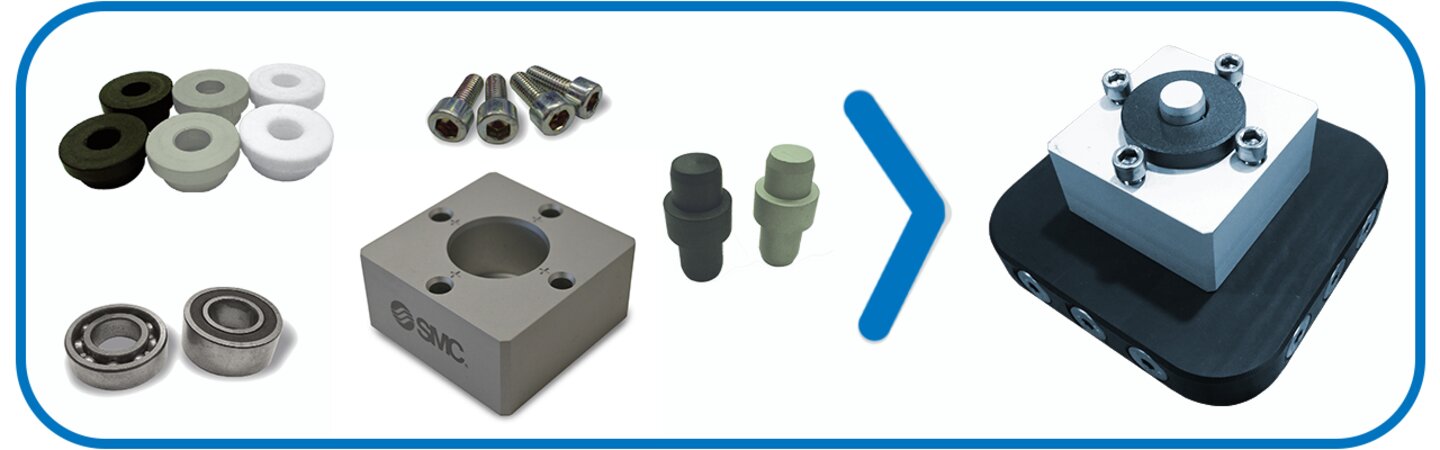

Turning mechanism