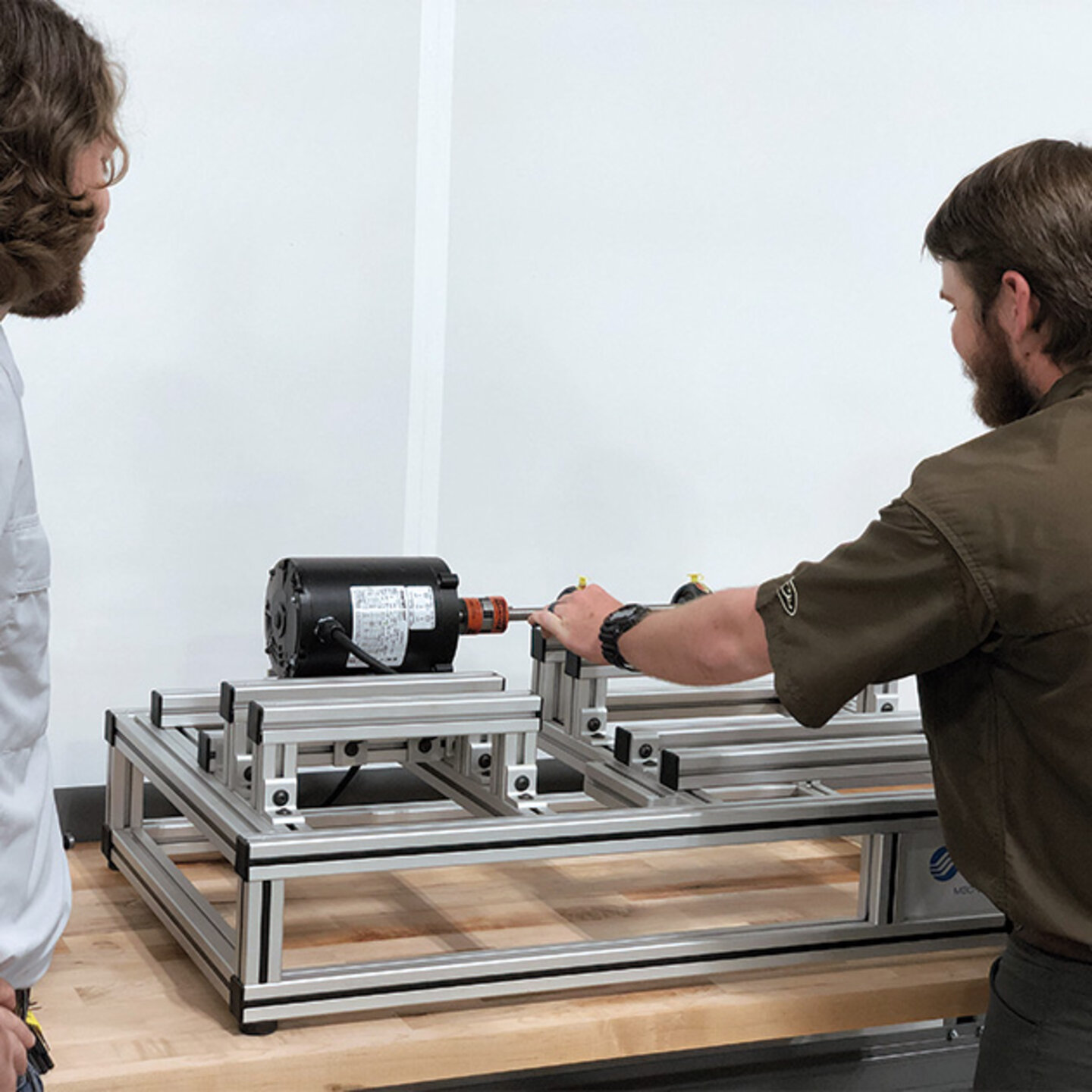

Develop skills in mechanical technology

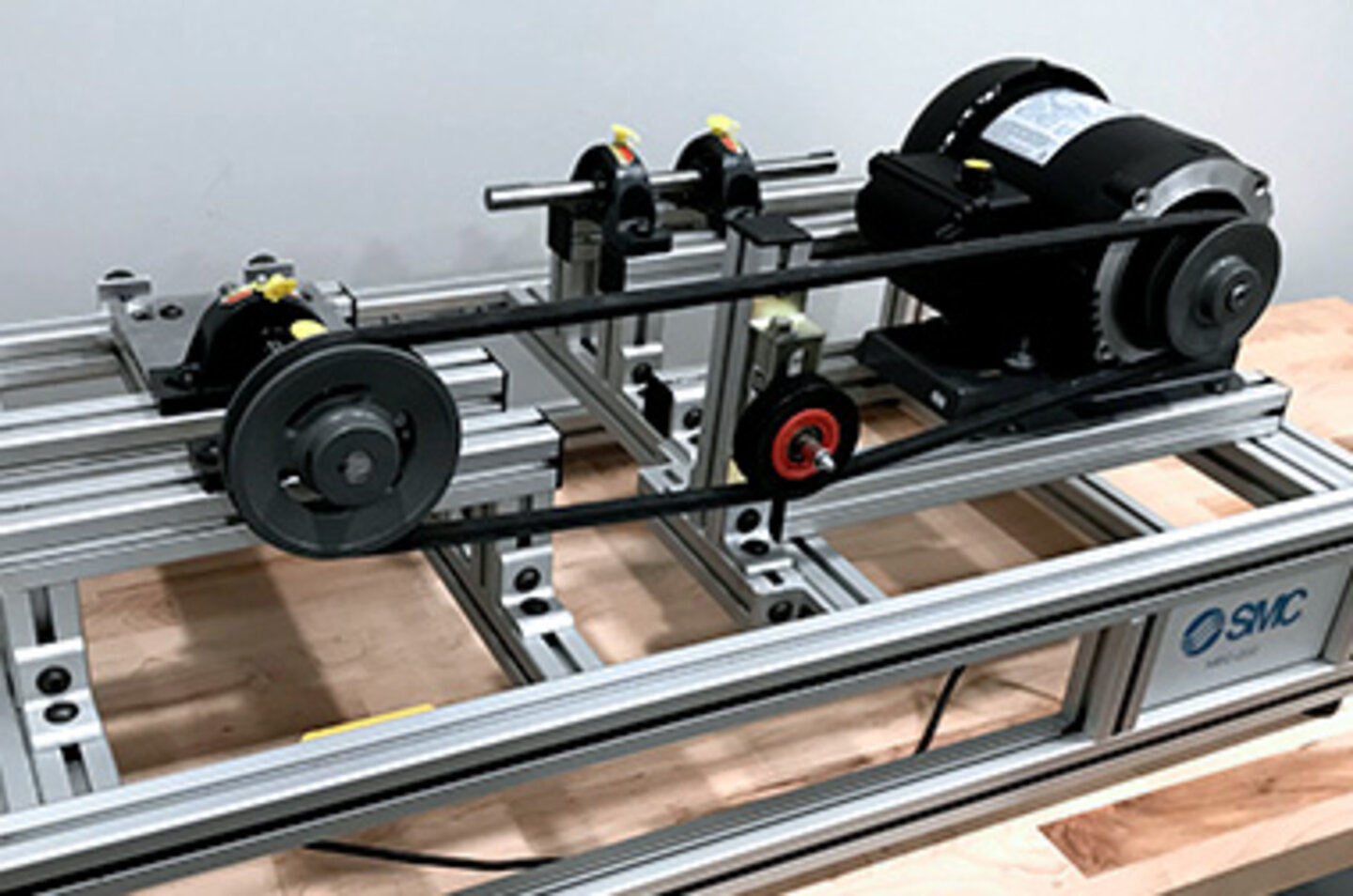

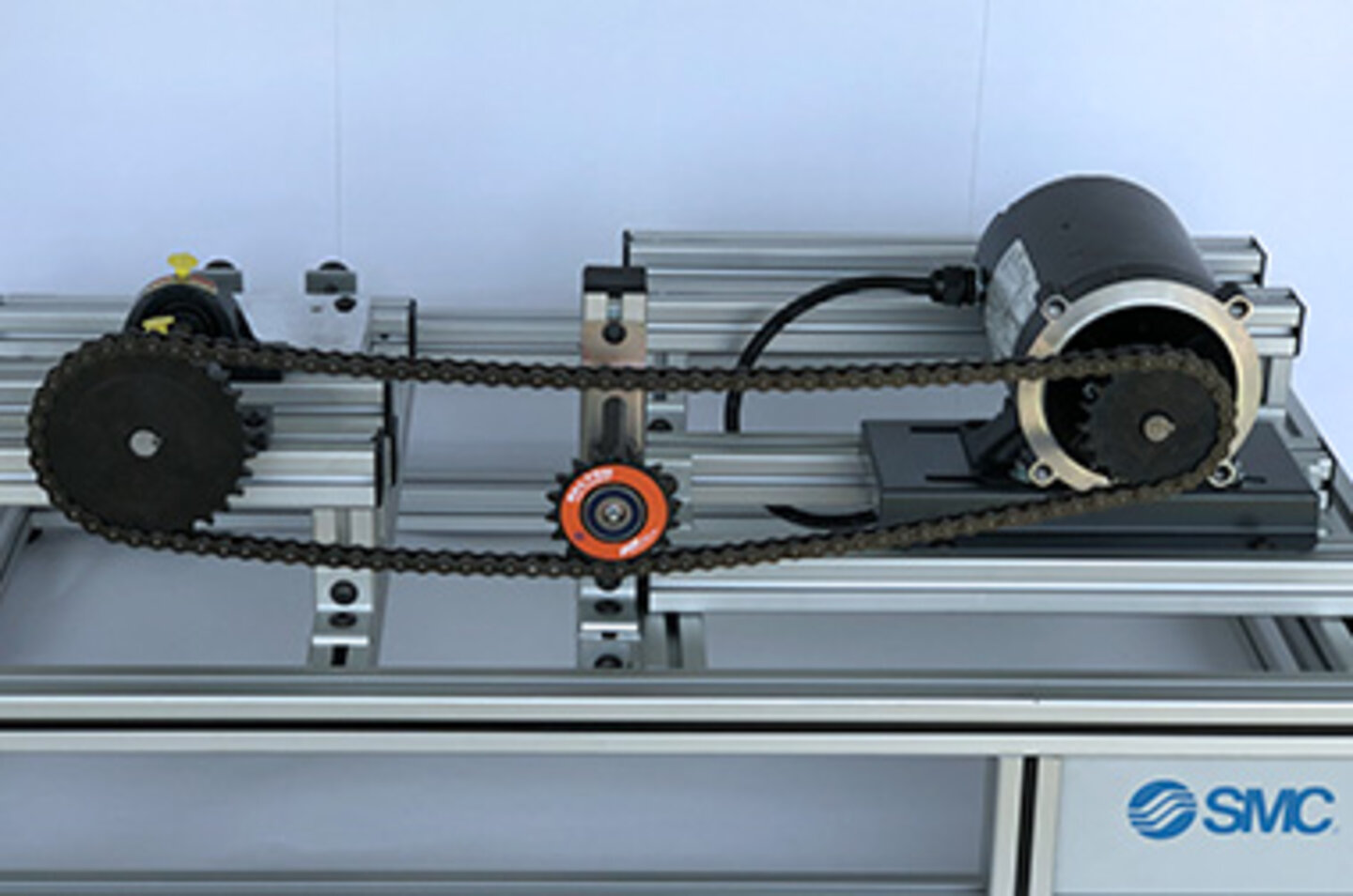

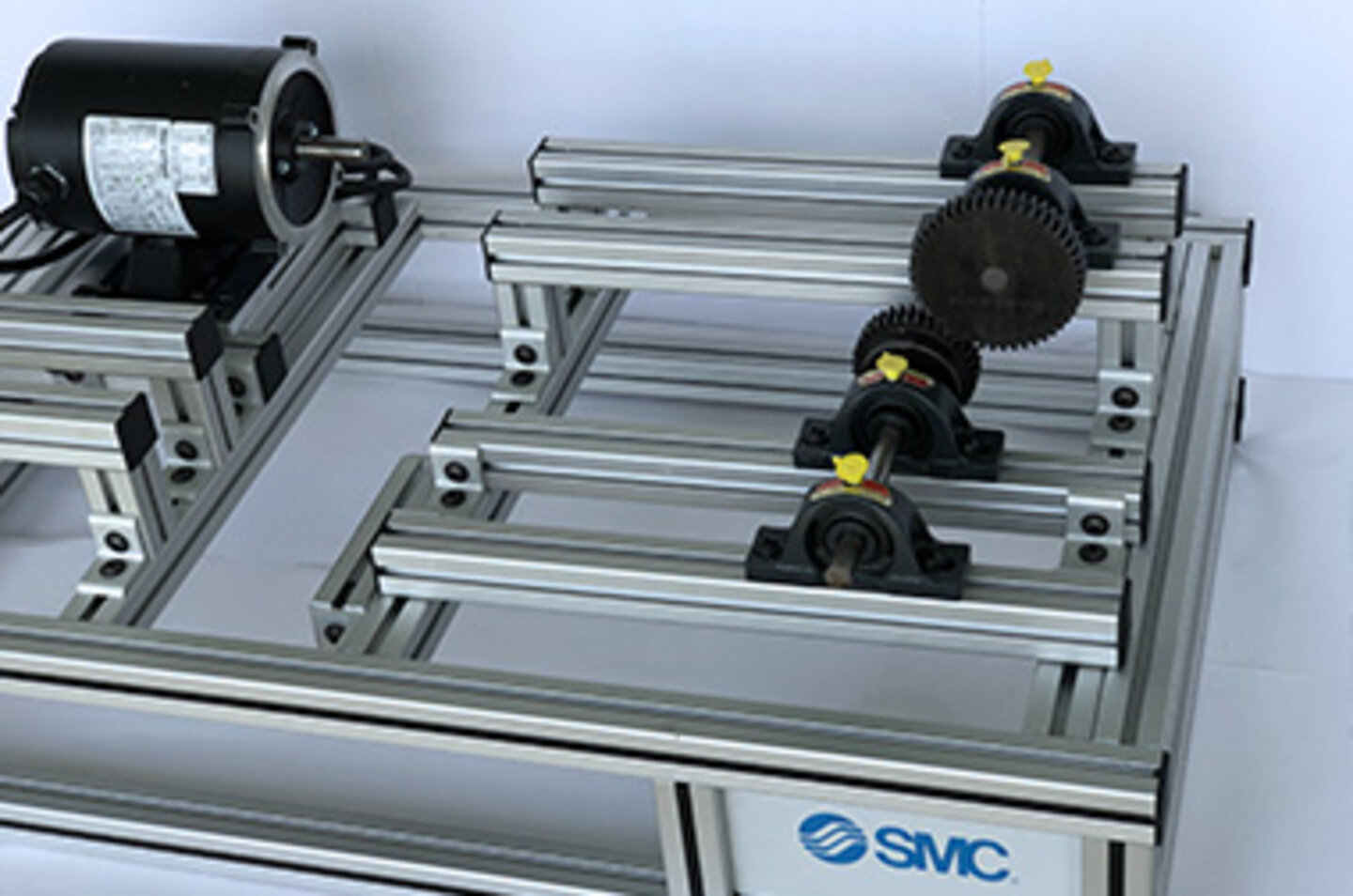

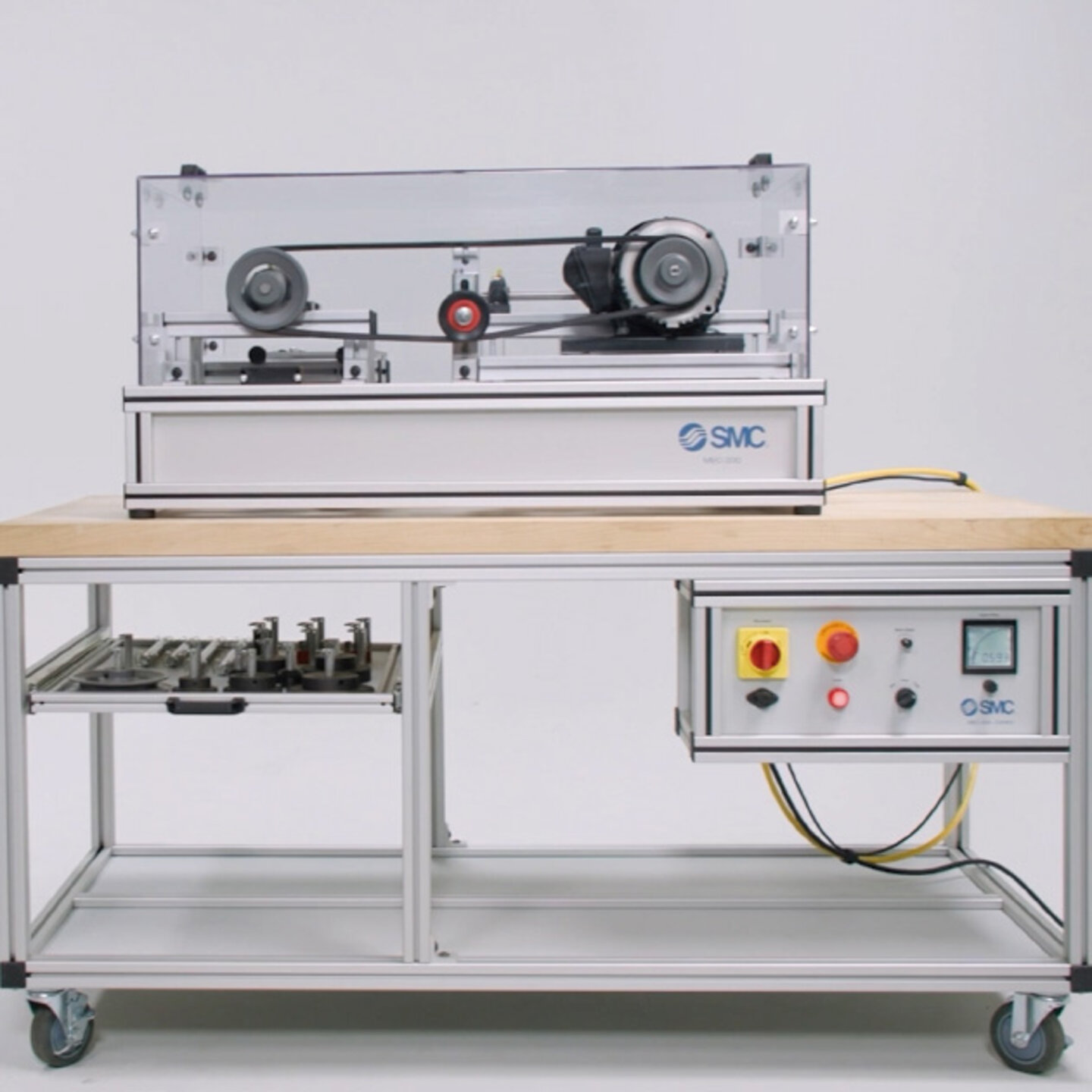

This system is designed to provide hands-on mechanical shaft alignment, pulley alignment, belt installation, gear alignment, chain installation, gear alignment practice and gear ratios.

Complete mechanical system

The complete system integrates five mechanical training modules into a single device, allowing multiple hands-on activities to be performed in a small space.

Multiple accessories

The system allows multiple optional accessories to be added, offering the possibility of working with industrial tools.

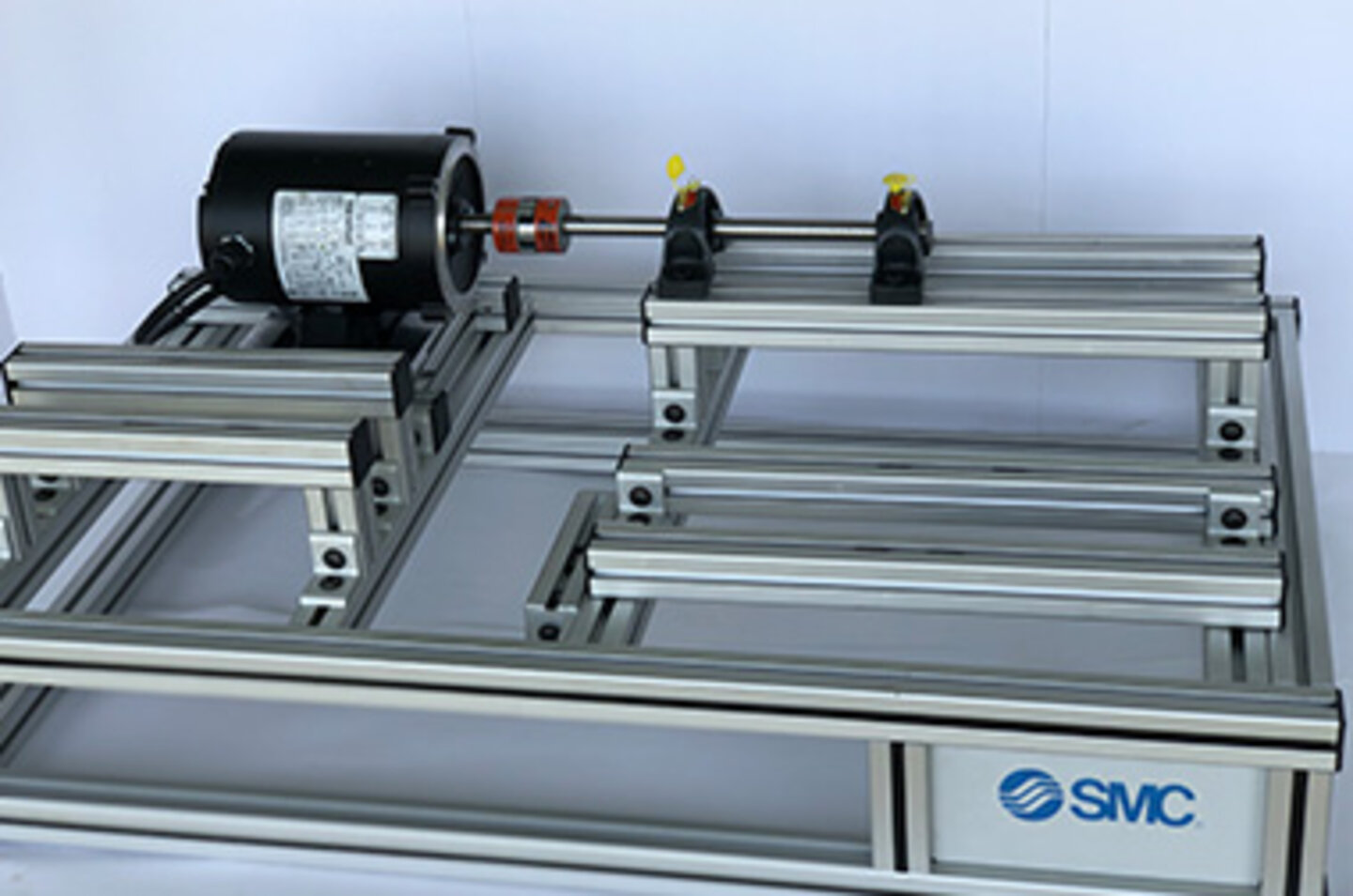

Industrial components

All the components of the MEC-200 system are the same as those used in industry, allowing users to work with real elements that they will find in the industrial environment.

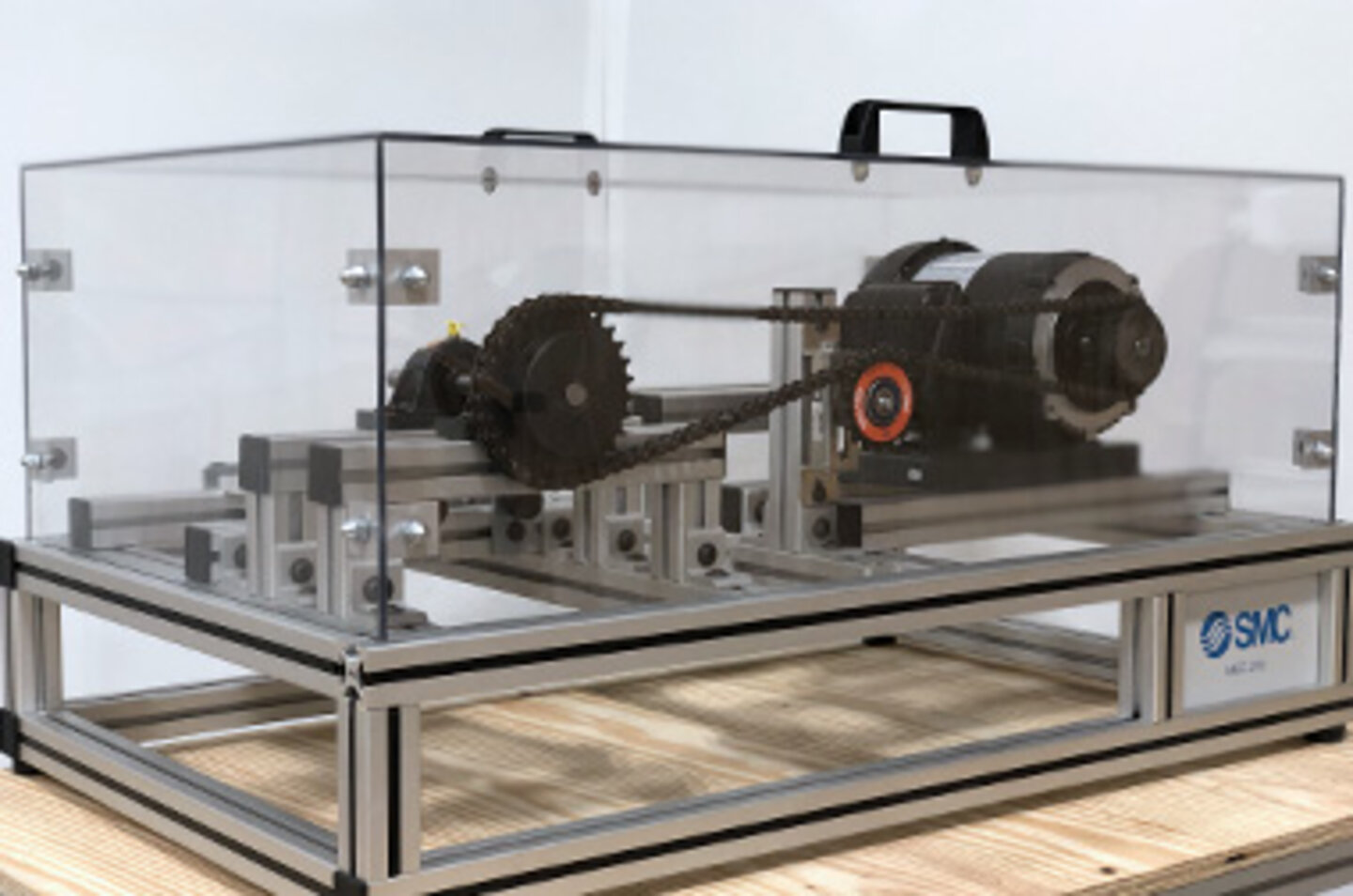

Safety features included

The system includes a safety enclosure connected to a safety relay offering extra safety when working with students by cutting the power when the cover is opened.