HAS-200 Special Edition - Industry 4.0

The HAS-200 Special Edition system with more technologies of Industry 4.0 allows the development of the most demanded competences in a highly automated environments of Industry 4.0.

The HAS-200 Special Edition system with more technologies of Industry 4.0 allows the development of the most demanded competences in a highly automated environments of Industry 4.0.

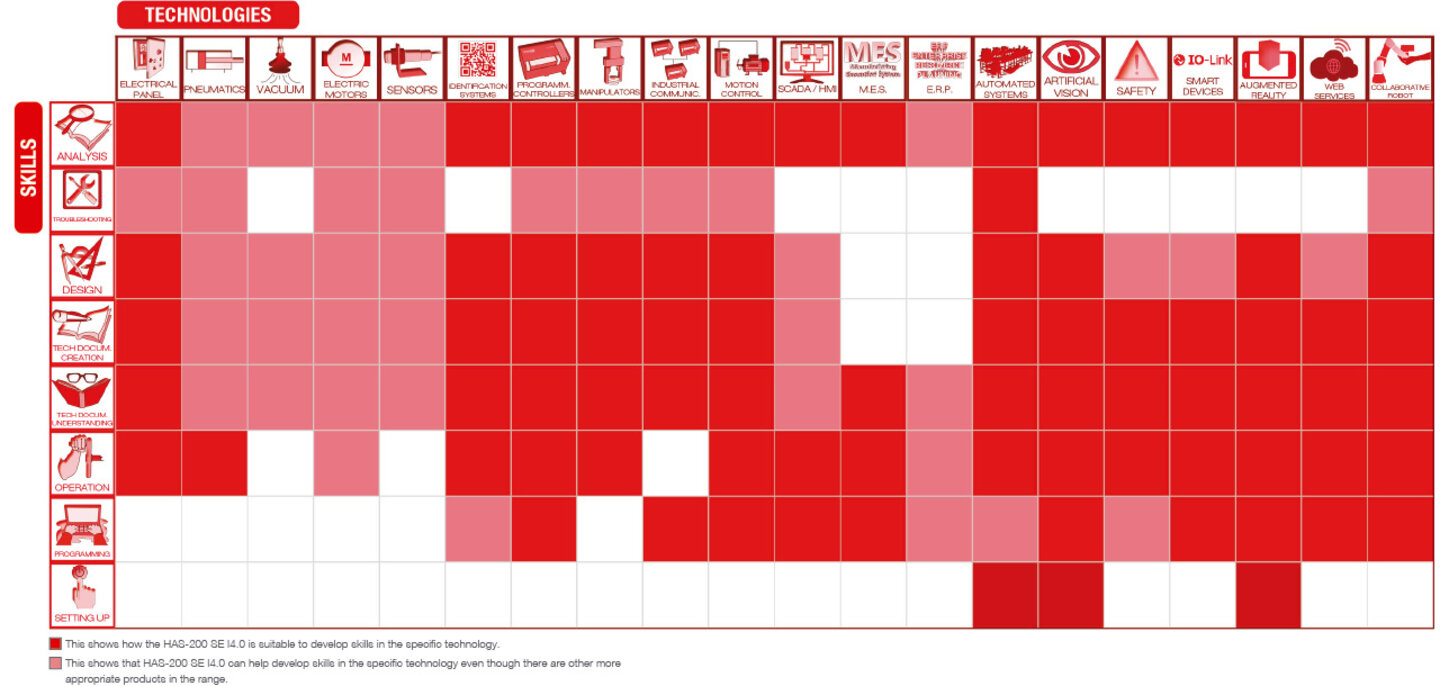

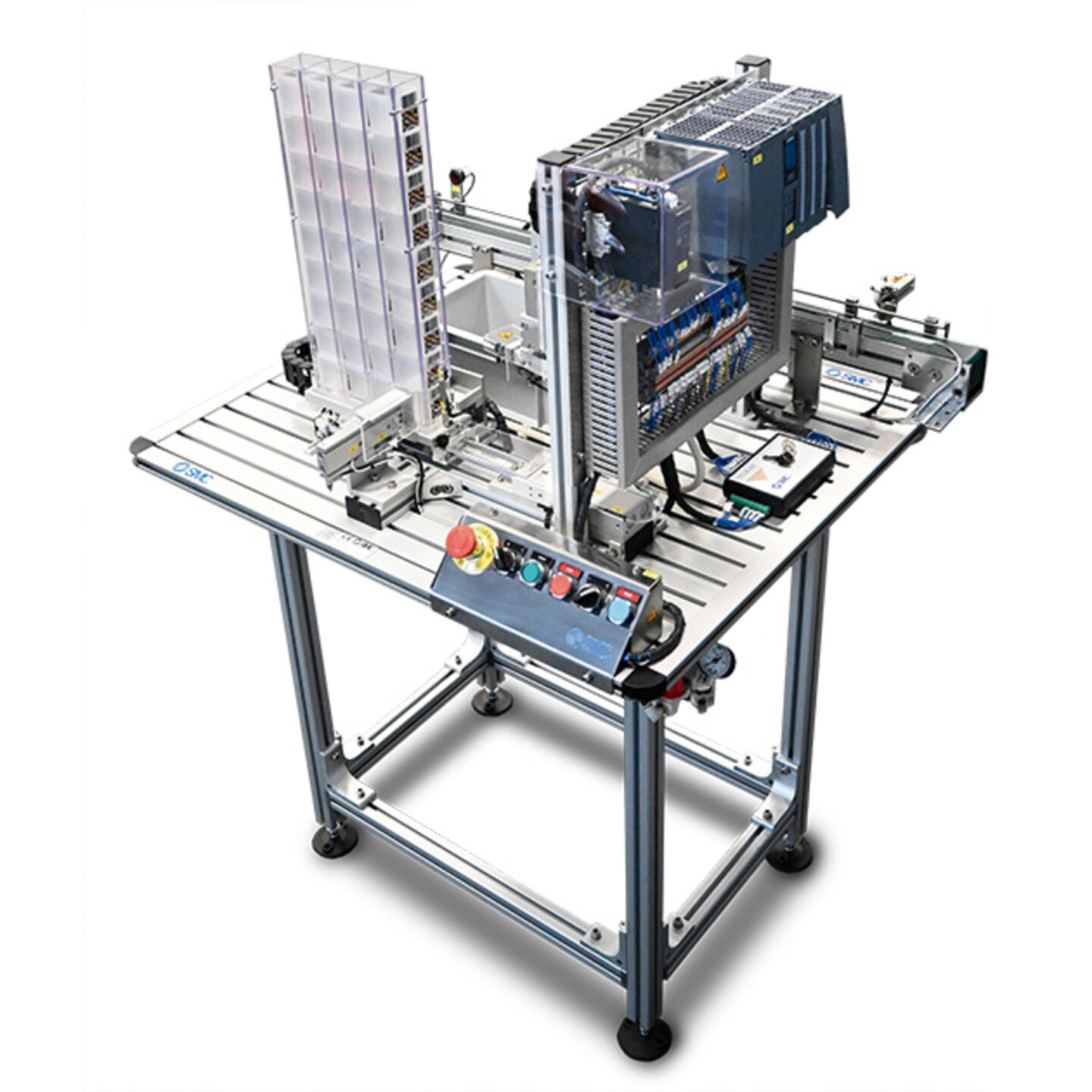

The HAS-200 Special Edition system with more technologies of Industry 4.0 allows the development of the most demanded skills in a highly automated environments of Industry 4.0. This technologically advanced didactic equipment allows the acquisition of the required skills for the different professional sectors. In addition to the technologies implemented in the standard edition of this system, the special version includes additional technologies that make this equipment the ideal solution to emulate the reality of a smart factory with the latest 4.0 technologies.

Image gallery

With this system you could...