Why is process control technology important and beneficial to industry?

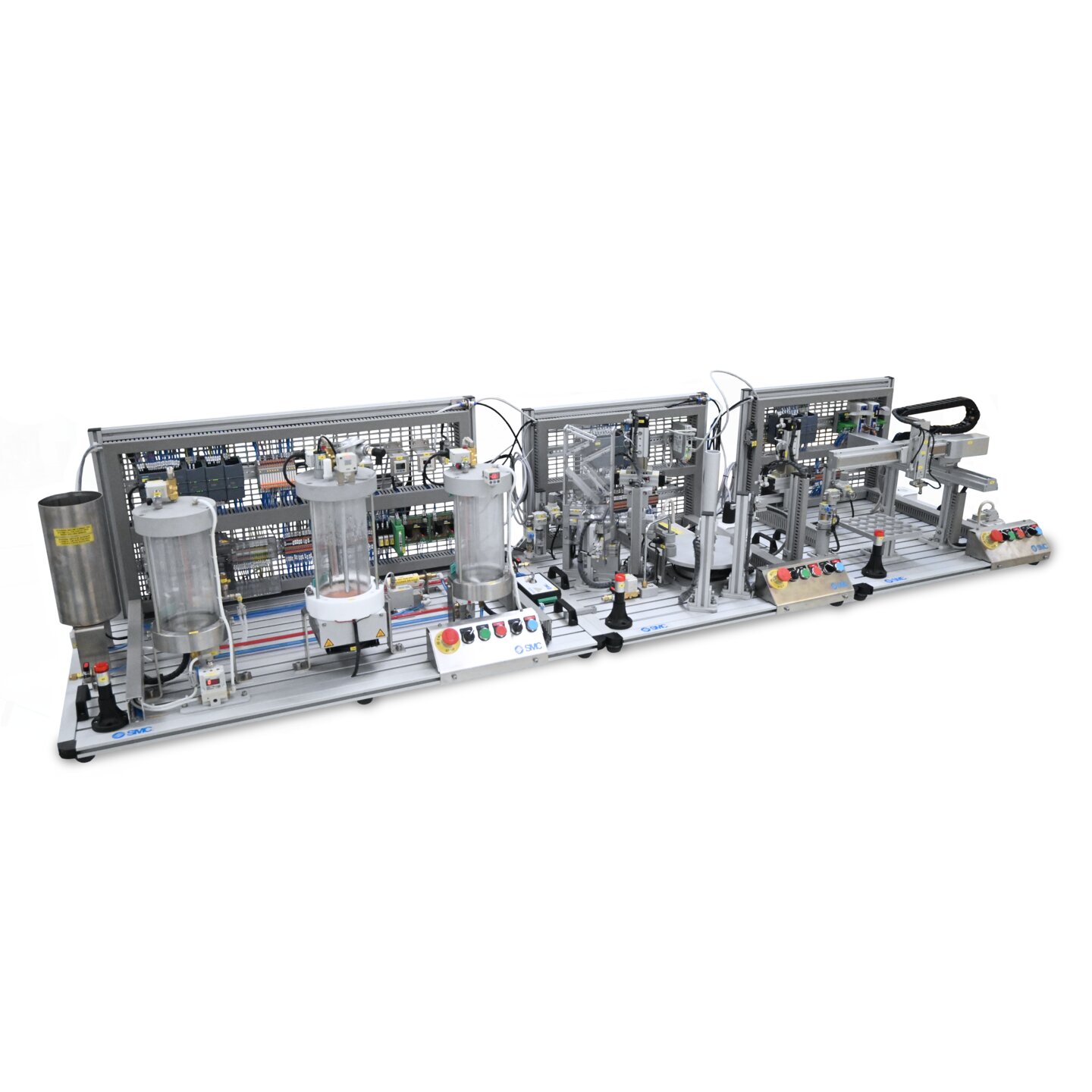

Some key features of this technology are:

- **Automation**: Process control systems can operate automatically, adjusting process variables without constant human intervention.

- **Accuracy and speed**: Process control technology can respond quickly to changes in the process and adjust conditions to keep variables within desired limits with high accuracy.

- **Security**: Helps ensure the safe operation of industrial processes by preventing hazardous or unsafe conditions.

- **Efficiency**: By keeping process variables within optimal ranges, greater operational efficiency is achieved, and costs are reduced.

- **Adaptability**: Process control systems can adapt to different situations and variations in process conditions.

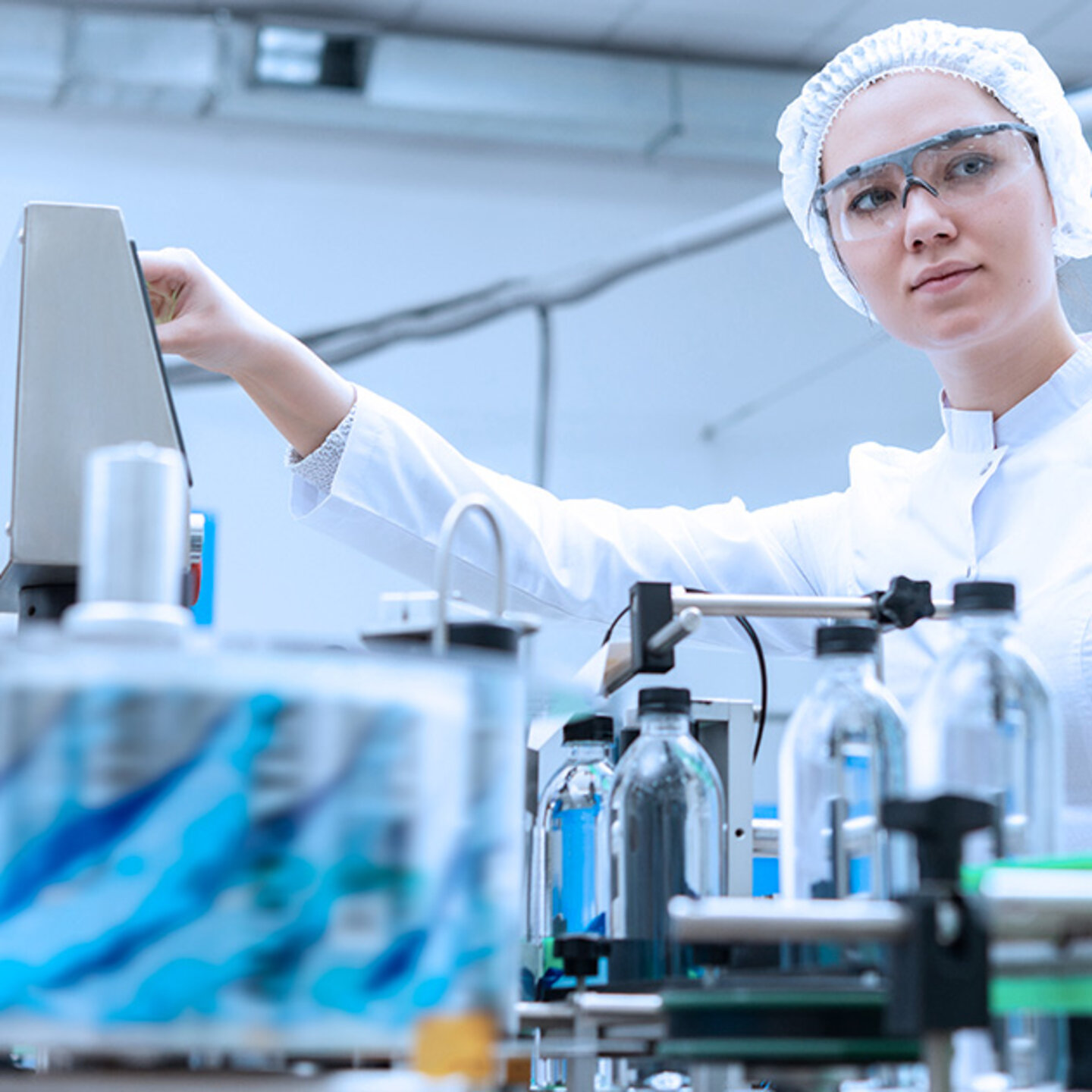

Process control technology is applied in a wide range of industries, such as food, automotive, energy, manufacturing, pharmaceuticals and many others, where its use is crucial to maintain stable and safe operations and to achieve consistent, high-quality production.