MAP-200 - Handling systems

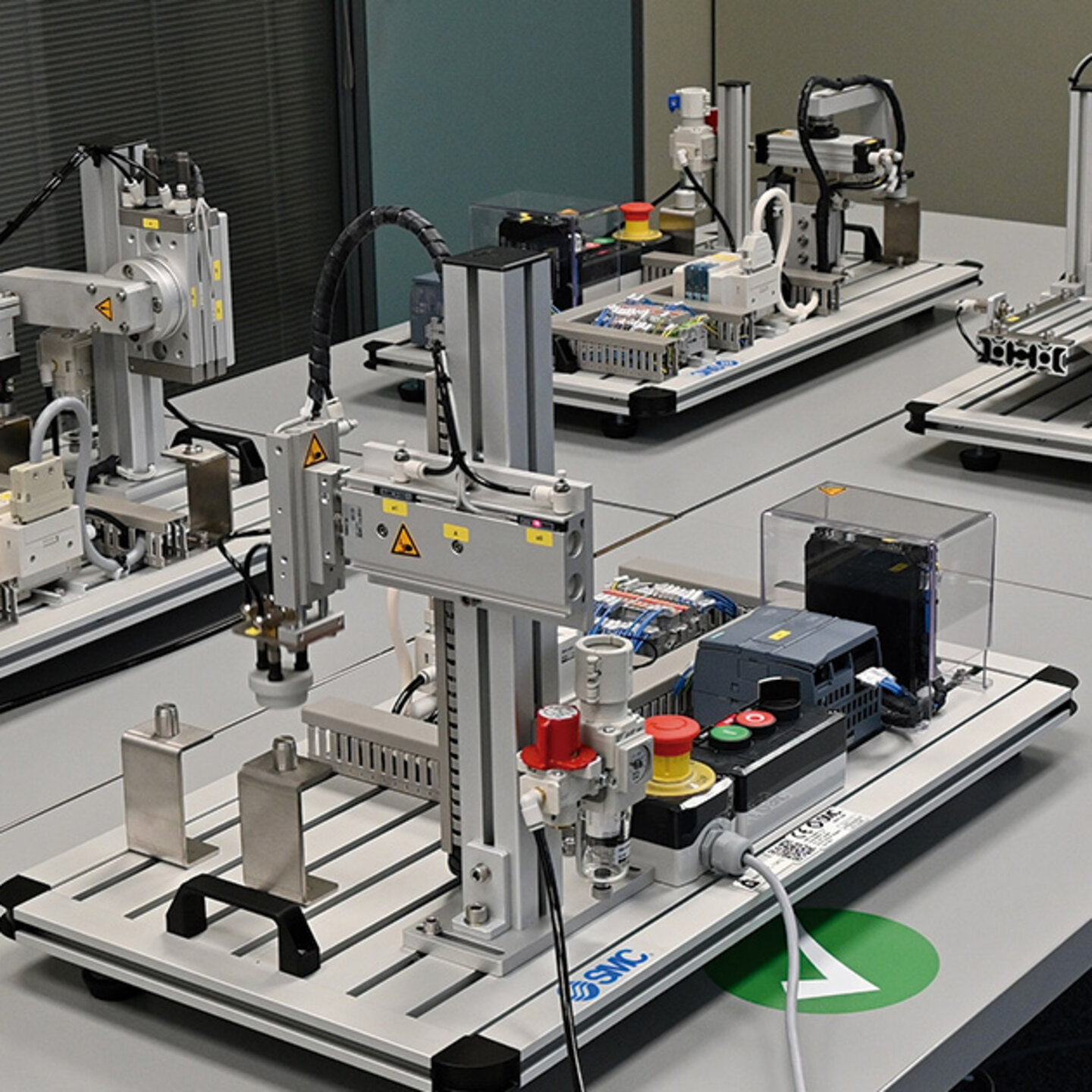

Seven independent and different training systems. Each of these carries out a simple assembly process by reproducing more complex processes found in industry.

Seven independent and different training systems. Each of these carries out a simple assembly process by reproducing more complex processes found in industry.

The MAP-200 series consists of seven independent and different training systems. Each of these carries out a simple assembly process by reproducing subsets of more complex processes found in industry. This video shows the most important features of each of the systems that make up the MAP-200 series of handling systems.

Image gallery

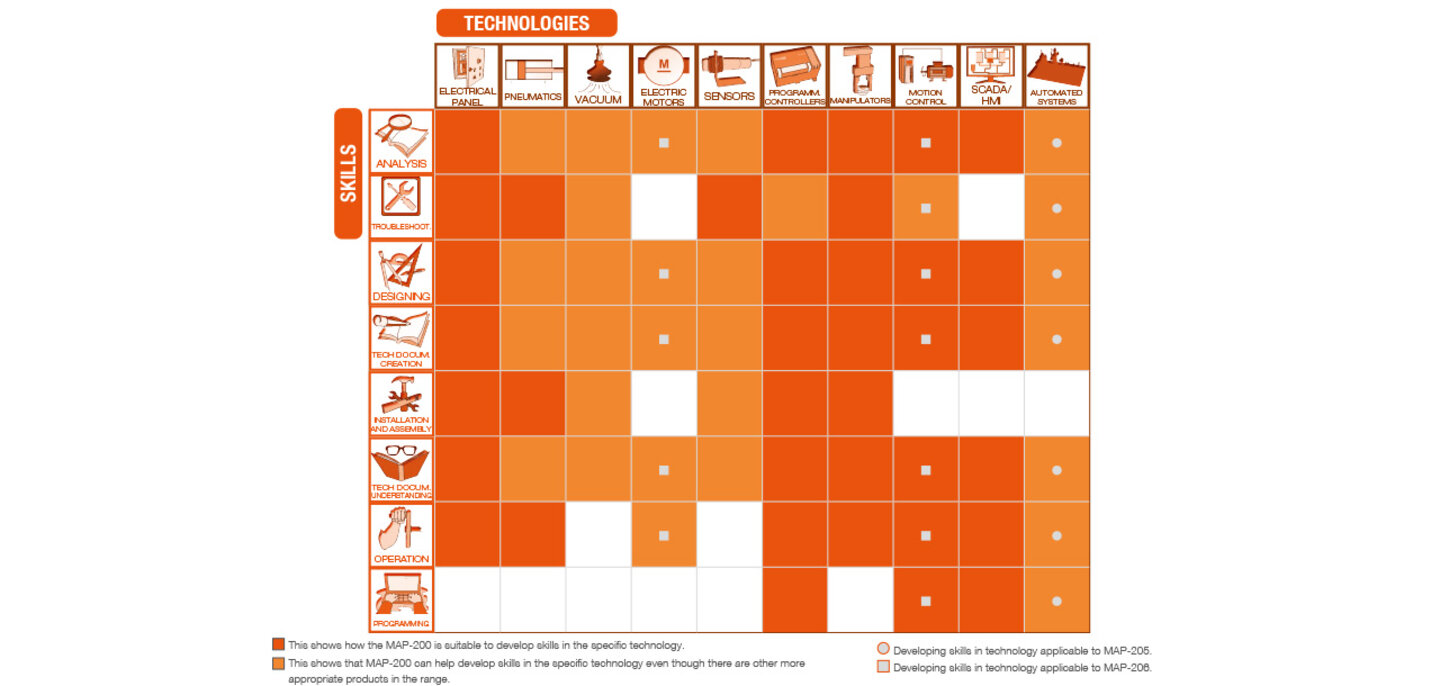

With this system you could...