ENS-200 - Energy saving trainer.

In a world where sustainability and energy efficiency are becoming more and more crucial, the ENS-200 is an innovative solution to optimise the use of compressed air in industrial facilities.

In a world where sustainability and energy efficiency are becoming more and more crucial, the ENS-200 is an innovative solution to optimise the use of compressed air in industrial facilities.

Energy saving in pneumatics

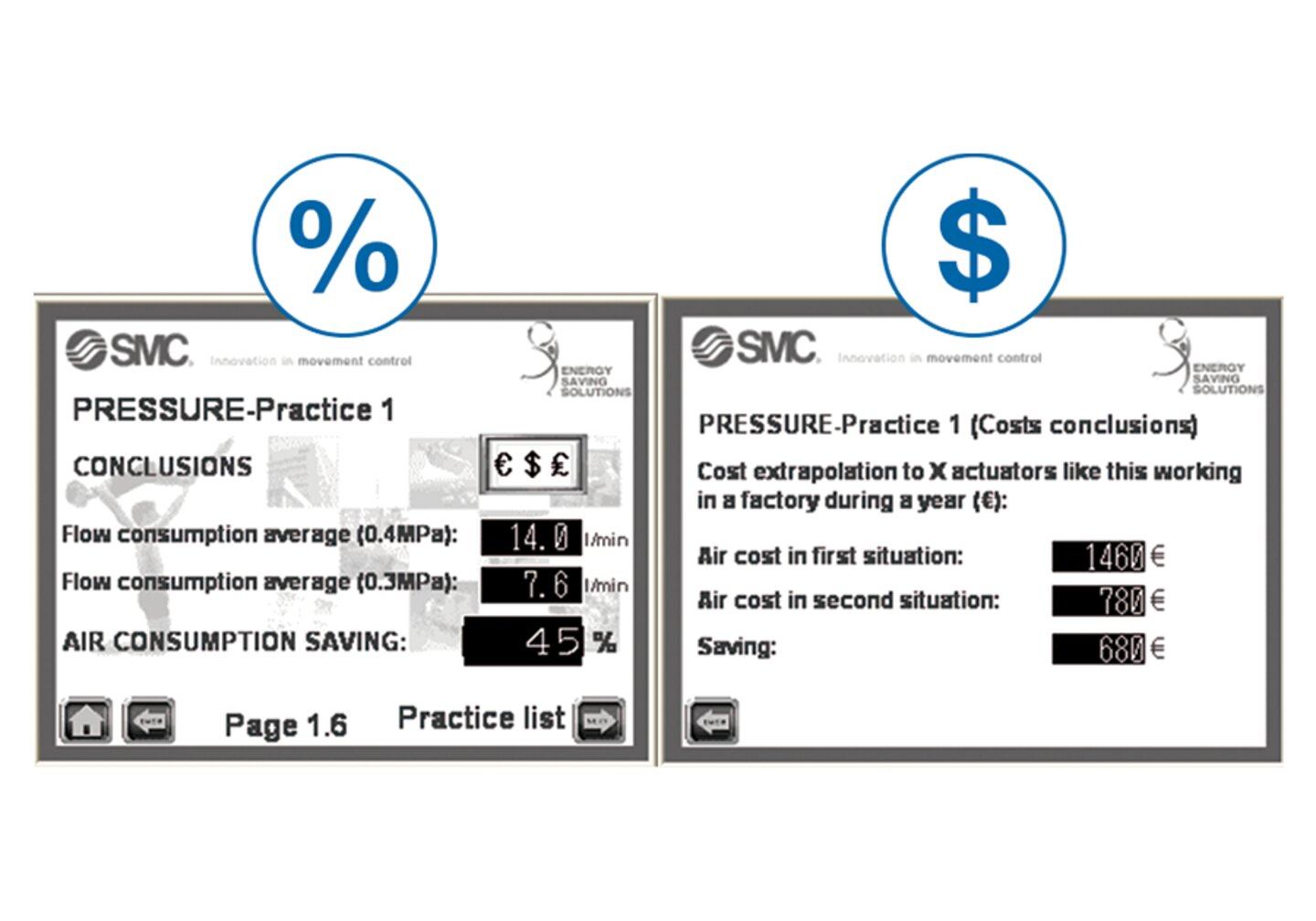

Pneumatic components must be set to just the right pressure. Avoid excessive pressure as consumption is proportional to work pressure.

To sectorise means to divide. It is possible to sectorise by differentiating between zones with different working pressure levels. It is also possible to sectorise by area, thereby minimising the impact of leaks when a zone is not active.

Monitoring means to measure. Measuring makes it possible to locate defects in the facility and assess what can be saved by correcting them. Measuring can be done constantly or occasionally. Monitoring also leads to prevention, i.e. knowing when a part of the facility is beginning to consume more energy due to leaks or other faults.

A dirty filter generates a drop in pressure. If this filter is not replaced, the pressure must be raised to continue meeting system requirements. This poor practice has a negative impact on consumption which leads to more compressed air generation.

With this system you could...